FITNIR Kappa

NIR spectroscopic analyzer that measures the kappa number of wet and dry kraft pulp and pulp sheets

Challenges

Kraft mills rely on the kappa number of pulp to estimate the extent of delignification of the cooking process. Kappa number is used as an input to automated control to optimize cooking yield and product quality. The standard, manual method to determine kappa number using potassium permanganate is slow and tedious and consumes a large amount of chemicals. Semi-automated or automated titration-based methods slightly reduce the time commitment, but still requires significant sample preparation and chemical usage. UV-visible light analysis methods are strongly dependent on species’ composition and can lead to errors, but most importantly it is not well suited for measuring high kappa numbers of kraft linerboard pulp.

FITNIR Solution

FITNIR Kappa utilizes NIR spectroscopy to measure the kappa number of kraft pulp. The spectral absorption features of lignin allow for the direct quantification of residual lignin on the pulp. Consequently, FITNIR Kappa does not rely on other parameters for measurement (i.e., the strength of chemicals, precise sample dry weight, reaction time, or a subjective colour change indicating end-point), automates sample preparation, and eliminates all associated chemicals. FITNIR Kappa provides kappa number rapidly, with excellent accuracy and repeatability. Analysis time is less than 20 seconds and the entire time to prepare the sample is less than 4 minutes. More importantly, the calibration models can be transferred from pulp-grade to pulp-grade without requiring major recalibration.

Properties Measured

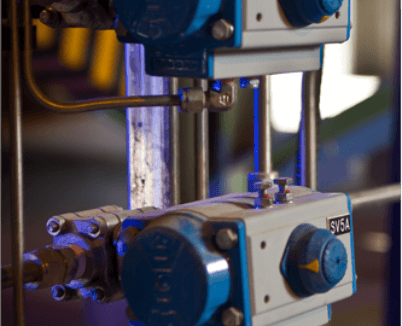

FITNIR Kappa measures the kappa number of both wet and dry pulp. FITNIR Kappa uses diffuse reflectance NIR spectroscopy as the basis of measurement. Energy from the NIR light penetrating the sample is absorbed by the lignin. Optics collect the diffused reflected light, registering its absorption on the infrared detector and generating the spectrum with its unique features. The spectral data from the analyzer is then correlated with a previously built calibration model to determine kappa number. FITNIR Kappa can also be configured to measure viscosity.

Key Benefits

- Simplified analysis for greater testing frequency

- Significantly reduces operator-to-operator variability, improving accuracy and repeatability

- Eliminates hazardous testing chemicals and reduces process chemicals by up to $150,000 per year

- Faster results for quicker adjustments, improving efficiency and profitability

- Improves customer satisfaction by adhering to quality standards and enabling product

segregation

Project highlights

International Paper

Domtar Corporation

Domtar Corporation

Orange, Texas, USA

Dryden, Ontario, Canada

Kamloops, BC, Canada

Kraft Linerboard

(2013)

SW Digester Blowline and Brownstock

(2015)

Pulp Sheet Kappa

(2015)

FITNIR Kappa

Measuring Kappa Number Using Nir Spectroscopy

Watch this short video demonstrating FITNIR Kappa and its key features for measuring wet and dry pulp, to help improve kraft pulp mill efficiency and profitability.