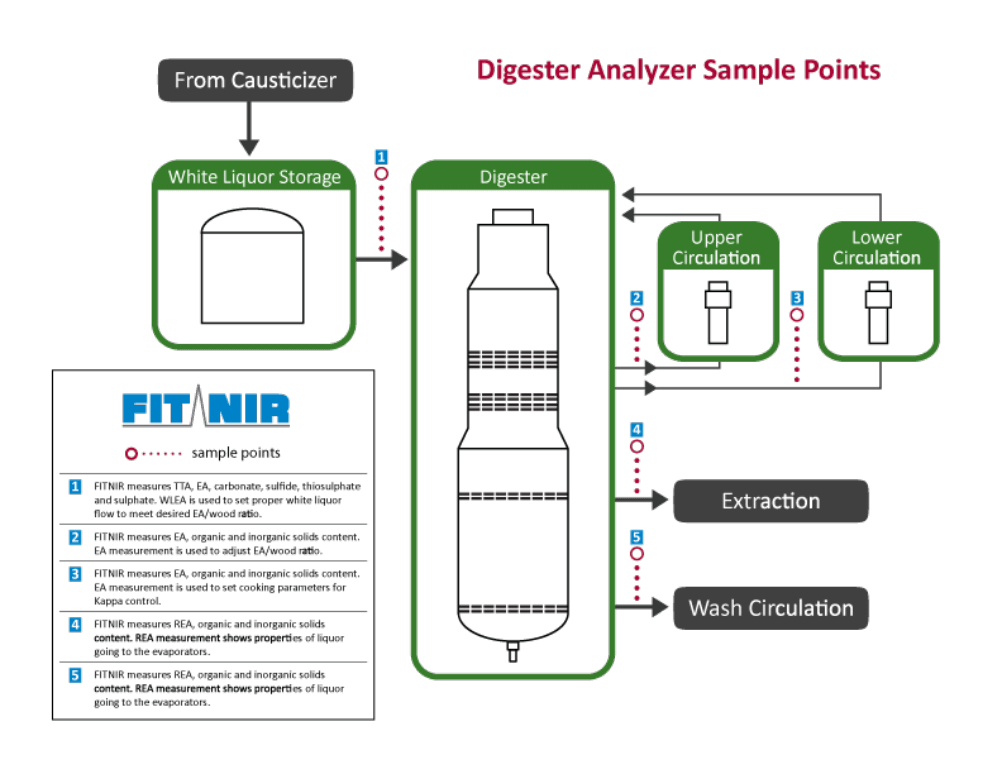

Digester

Proven FT-NIR application for digester optimization

Digester Challenges

Alkali measurements are used to determine chemical consumption during the various Kraft cooking phases in the digester. These measurements are widely accepted as standard monitoring information, as they provide a solid basis for cooking management and digester optimization. Traditional measurement methods, such as conductivity and autotitration, tend to foul and drift while only inferring actual values.

FITNIR Solution

FITNIR’s FT-NIR technology offers the most comprehensive and accurate measurements of true pulp liquor properties measurements necessary for an optimal digester environment, devoid of fouling or drifting issues.

Our analyzers reliably and accurately provide white liquor EA (Effective Alkali) and sulphidity, as well as black liquor REA (Residual Effective Alkali) at the various cooking zones. Control strategies using reliable data from our analyzers can significantly reduce kappa variation, overcooking and rejects while increasing pulp quality.

Properties Measured

FITNIR’s Digester analyzer application measures black liquor compositions:

- REA

- Total Solids*

- Organic Solids*

- Lignin

- Inorganic Solids*

- Density

*FITNIR Online measurement only

Key Benefits

- $1 – 2M savings/year

- Reduced off-grade pulp

- 3 – 6 months average ROI

- Improved digester control

- More efficient white liquor consumption

- Reduced kappa variability

- Fewer lab tests required

- Decreased bleaching cost

- Improved yield

- Reduced overcooking and rejects for improved pulp quality

Project highlights

Weyerhaeuser, Grande Prairie Mill

CANFOR Pulp, Northwood Pulp Mill

Mill in Eastern Canada

Catalyst Paper

Grande Prairie, AB, Canada

Prince George, BC, Canada

Eastern Canada

Crofton, BC, Canada

FITNIR Benchtop

FITNIR Online

FITNIR Online

FITNIR Online

What process area of your pulp mill would you like to optimize?

Learn more about our Applications and FITNIR Technologies.