Brownstock Washer

FT-NIR Application for Brownstock Washer Optimization

Brownstock Washer Challenges

Brownstock washing is an integral part of the chemical recovery process. A high efficiency brownstock washing operation maximizes washing efficiency and the recovery of sodium and dissolved organics with optimal dilution factor. However, it is inevitable that some of the macro-molecules, such as lignin, become entrained within the pulp causing the filtrate to interfere with the bleaching process. This increases bleaching costs by consuming more bleaching chemicals.

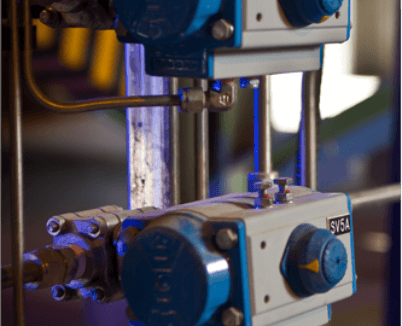

FITNIR Solution

The ability of FITNIR’s analyzers to measure brownstock filtrate plays a critical role in optimizing the bleaching chemical charge, particularly for the first bleaching stage. Knowing the carryover allows for optimal compensation of ClO2 charge, while minimizing occurrences of over-charging of the first bleaching stage.

Properties Measured

FITNIR’s Brownstock Washer analyzer application measures:

- Chemical Oxygen Demand (COD) of the washed pulp filtrate

Key Benefits

- $0.3 – 0.6M savings/year

- 12 months ROI

- Enables optimal compensation of ClO2 charge

- Minimizes the amount of over-charging of the first bleaching stage

Project Highlights

As a requested by the Process Engineer, FITNIR collaborated with Canfor Northwood pulp mill to develop the measurements. The trial is ongoing and data analysis is being carried out to correlate process variability with measurement signals. A control strategy is also being considered.

What process area of your pulp mill would you like to optimize?

Learn more about our Applications and FITNIR Technologies.