LMS (Sólidos de Lama Calcária)

Aplicação FT-NIR comprovada para sólidos de lama de cal

Desafios

A determinação do teor de sólidos da lama de cal para operações de forno depende principalmente do teste de secagem em estufa de amostras manuais da linha de processo. Existem muitos desafios com a amostragem manual: amostragem pouco frequente, perigos inerentes à amostragem de transportadores em movimento, métodos de teste em que as amostras evaporam imediatamente, bem como dificuldade em recuperar amostras representativas. Os moinhos são desafiados a encontrar soluções que forneçam dados de sólidos de lama frequentes e de alta qualidade para otimizar as operações do forno. Os medidores de peso de correia fornecem o peso total, mas não consideram o teor de umidade. Algumas medições de condutância disponíveis exigem que uma sonda esteja em contato com a lama de cal em movimento, o que representa problemas mecânicos da sonda e uma perda de medições de qualidade.

Solução FITNIR

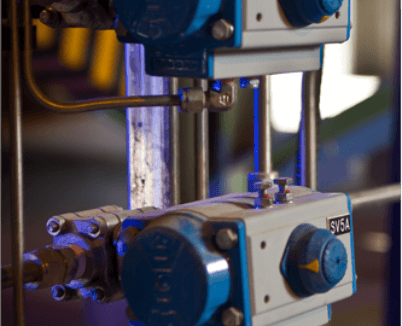

O FITNIR LMS aborda a lacuna na frequência de medição, bem como os desafios mecânicos inerentes à tecnologia disponível hoje. Com base na espectroscopia NIR, o FITNIR LMS caracteriza o conteúdo de sólidos de lama de cal e tem o potencial de analisar outras propriedades de óxido de metal (ou seja, Al2O3, Fe2O3, etc.). A medição on-line é realizada por meio de um cabeçote de sensoriamento remoto sobre o transportador, situado acima do transportador, que não entra em contato com a lama de cal em movimento.

Uma fonte de luz de banda larga ilumina a amostra de lama de cal, e sua energia é absorvida pelas moléculas da amostra. A luz difusamente refletida é coletada e analisada, medindo diretamente o conteúdo de sólidos com base na absorção de água. As medições são feitas em tempo real a uma frequência média de uma saída de medição por minuto.

Propriedades Medidas e Aplicações

O FITNIR LMS mede o conteúdo de sólidos de lama que alimenta o forno, fornecendo informações para controle de feedback do espessador de lama e controle de feedforward do forno FET (temperatura final de alimentação). Consequentemente, o consumo de combustível e os potenciais problemas operacionais do forno são reduzidos. Quando usado com um medidor de peso, o fluxo de massa seca pode ser calculado.

Principais benefícios

Benefícios do Digestor

- Reduzir a variação de sólidos da lama, resultando em menor FET

- Baixa manutenção

- Reduzir o consumo de combustível (fóssil) e os custos de energia

- Reduzir problemas operacionais do forno, como possíveis anéis de lama

- Aumentar a frequência das medições de sólidos de lama

- Reduza o risco para operadores associado à amostragem em transportadores em movimento

- Veja também o aplicativo relacionado, FITNIR MC, que mede o teor de umidade.

Qual área de processo da sua fábrica de celulose você gostaria de otimizar?

Saiba mais sobre nossos aplicativos e tecnologias FITNIR.