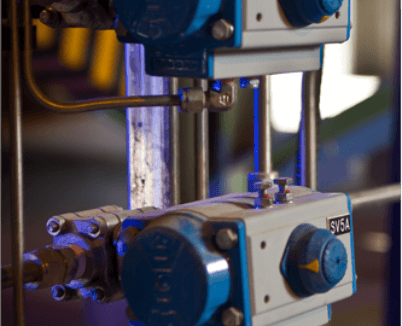

Máquina de lavar Brownstock

Aplicação FT-NIR para otimização de lavadora de brownstock

Desafios da lavadora Brownstock

A lavagem de brownstock é parte integrante do processo de recuperação química. Uma operação de lavagem de brownstock de alta eficiência maximiza a eficiência da lavagem e a recuperação de sódio e orgânicos dissolvidos com fator de diluição ideal. No entanto, é inevitável que algumas das macromoléculas, como a lignina, sejam arrastadas para dentro da polpa, fazendo com que o filtrado interfira no processo de branqueamento. Isso aumenta os custos de branqueamento ao consumir mais produtos químicos de branqueamento.

Solução FITNIR

A capacidade dos analisadores do FITNIR de medir o filtrado de brownstock desempenha um papel crítico na otimização da carga química de branqueamento, particularmente para o primeiro estágio de branqueamento. Conhecer o carryover permite a compensação ideal da carga de ClO2, ao mesmo tempo em que minimiza ocorrências de sobrecarga do primeiro estágio de branqueamento.

Propriedades medidas

As medidas de aplicação do analisador Brownstock Washer da FITNIR:

- Demanda química de oxigênio (DQO) do filtrado de polpa lavada

Principais benefícios

- $0.3 – 0,6M de economia/ano

- 12 meses de ROI

- Permite compensação ideal da carga de ClO2

- Minimiza a quantidade de sobrecarga do primeiro estágio de branqueamento

Destaques do Projeto

Conforme solicitado pelo Engenheiro de Processo, a FITNIR colaborou com a fábrica de celulose Canfor Northwood para desenvolver as medições. O teste está em andamento e a análise de dados está sendo realizada para correlacionar a variabilidade do processo com os sinais de medição. Uma estratégia de controle também está sendo considerada.

Qual área de processo da sua fábrica de celulose você gostaria de otimizar?

Saiba mais sobre nossos aplicativos e tecnologias FITNIR.