フィトニールMC

制御戦略の統合のための正確で信頼性の高い水分含有量測定を提供

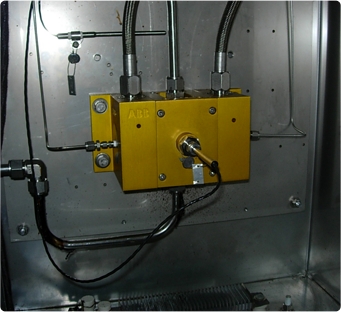

FITNIR MC は NIR 分光法を利用して、制御戦略の統合のために、消化槽への木材チップまたは発電ボイラーへの豚燃料の正確で信頼性の高い水分含有量測定を提供します。FITNIR MC の高品質でタイムリーなデータは、コスト削減とプロセス最適化に不可欠な原料特性を明確にします。

FITNIR MC を制御戦略と組み合わせて実装すると、生産量が全体で 2.5% 増加し、工場の収益が年間 $3.5 百万増加すると推定されます。乾燥チップの供給速度の大きな変動を排除することで、化学薬品の投与と容器の水圧負荷をより一貫して制御できるため、全体的な消化槽の動作が改善され、パルプ品質のばらつきが軽減されると期待されます。

主な特徴

- フルスペクトルNIRセンサー

- 非接触型コンベア上システム

- リアルタイムのオンライン測定

- 高精度(+/-2.5%)と再現性

- メンテナンスは最小限で済む

- 消化槽および発電ボイラーの用途

- 拡張可能なアプリケーション

- 堅牢で移転可能な校正モデル

- 凍結した材料と凍結していない材料の両方を測定可能

- 工業設計の分析装置

- DCSと直接通信する社内ソフトウェアとデータベース

FITNIR MCで利用可能なアプリケーションは次のとおりです。

主なメリット

消化槽の利点

- 消化槽の生産制御と生産速度を向上

- 白液添加量の削減による化学薬品の節約

- カッパ数の変動性を低減

- 給餌ロスと機器損傷のリスクを排除

パワーボイラーのメリット

- 発電ボイラーの不安定性とダウンタイムを削減

- 森林バイオマスを最大限に活用することで燃料消費コストを削減

- 化石燃料の消費と環境への影響を削減

- より信頼性が高く収益性の高い蒸気と電力の生産

- MCの変化を早期に検出することでバイオマス燃料の価格予測を改善

パルプ工場のどのプロセス領域を最適化したいですか?

当社のアプリケーションと FITNIR テクノロジーの詳細をご覧ください。