消化槽

消化槽の最適化のための実証済みの FT-NIR アプリケーション

消化槽の課題

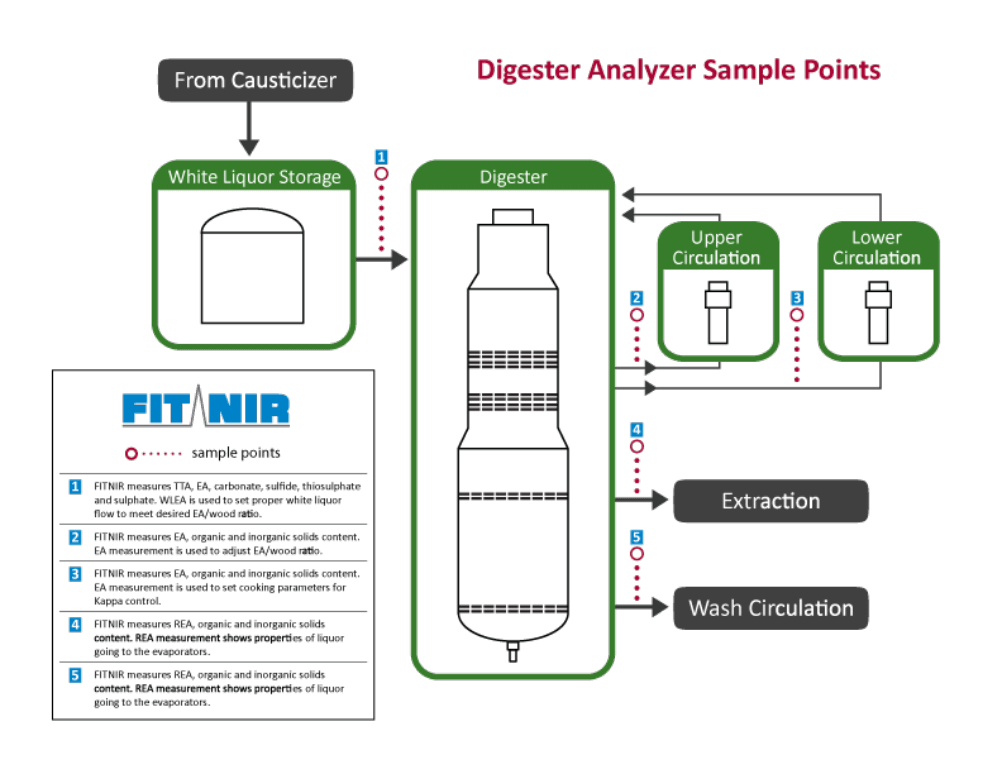

アルカリ測定は、蒸解釜内のさまざまなクラフト蒸解段階での化学物質消費量を決定するために使用されます。これらの測定は、蒸解管理と蒸解釜の最適化の確固たる基盤となるため、標準的な監視情報として広く受け入れられています。導電率や自動滴定などの従来の測定方法は、実際の値を推測するだけなので、汚れやドリフトが発生する傾向があります。

FITNIRソリューション

FITNIR の FT-NIR テクノロジーは、汚れや漂流の問題のない最適な蒸解槽環境に必要な、真のパルプ液特性の最も包括的かつ正確な測定を提供します。

当社の分析装置は、さまざまな蒸解ゾーンで白液の EA (有効アルカリ) と硫化度、および黒液の REA (残留有効アルカリ) を信頼性と精度で提供します。当社の分析装置から得られる信頼性の高いデータを使用した制御戦略により、カッパ値の変動、蒸解過多、不良品を大幅に削減しながら、パルプの品質を向上させることができます。

測定された特性

FITNIR の Digester 分析アプリケーションは、黒液の組成を測定します。

- レア

- 総固形分*

- 有機固形物*

- リグニン

- 無機固体*

- 密度

*FITNIRオンライン測定のみ

主なメリット

- $1 – 年間200万の節約

- 不良パルプの削減

- 平均3~6か月のROI

- 改良された消化槽制御

- 白液の消費効率向上

- カッパ変動の減少

- 必要な検査が少なくなる

- 漂白コストの削減

- 収量の向上

- 過度な加熱や不良品を減らしてパルプ品質を向上

プロジェクトのハイライト

ウェイアーハウザー、グランドプレーリーミル

CANFOR パルプ、ノースウッド パルプ工場

カナダ東部の工場

触媒紙

グランドプレーリー、アルバータ州、カナダ

カナダ、ブリティッシュコロンビア州プリンスジョージ

カナダ東部

クロフトン、ブリティッシュコロンビア州、カナダ

FITNIR ベンチトップ

FITNIRオンライン

FITNIRオンライン

FITNIRオンライン

パルプ工場のどのプロセス領域を最適化したいですか?

当社のアプリケーションと FITNIR テクノロジーの詳細をご覧ください。