FITNIR Kappa

Penganalisis spektroskopi NIR yang mengukur jumlah kappa pulp kraft basah dan kering serta lembaran pulp

Tantangan

Pabrik Kraft mengandalkan angka kappa pulp untuk memperkirakan tingkat delignifikasi dari proses pemasakan. Angka kappa digunakan sebagai input untuk kontrol otomatis guna mengoptimalkan hasil pemasakan dan kualitas produk. Metode manual standar untuk menentukan angka kappa menggunakan kalium permanganat lambat dan membosankan serta menghabiskan banyak bahan kimia. Metode berbasis titrasi semi-otomatis atau otomatis sedikit mengurangi komitmen waktu, tetapi masih memerlukan persiapan sampel dan penggunaan bahan kimia yang signifikan. Metode analisis sinar UV-tampak sangat bergantung pada komposisi spesies dan dapat menyebabkan kesalahan, tetapi yang terpenting metode ini tidak cocok untuk mengukur angka kappa yang tinggi dari pulp linerboard kraft.

Solusi FITNIR

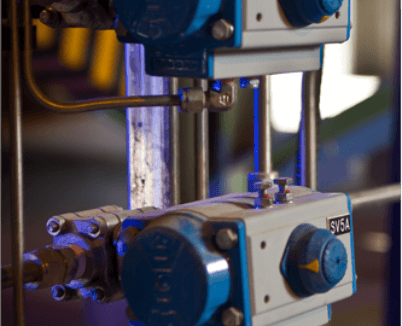

FITNIR Kappa menggunakan spektroskopi NIR untuk mengukur angka kappa pulp kraft. Fitur penyerapan spektral lignin memungkinkan kuantifikasi langsung lignin residual pada pulp. Akibatnya, FITNIR Kappa tidak bergantung pada parameter lain untuk pengukuran (yaitu, kekuatan bahan kimia, berat kering sampel yang tepat, waktu reaksi, atau perubahan warna subjektif yang menunjukkan titik akhir), mengotomatiskan persiapan sampel, dan menghilangkan semua bahan kimia terkait. FITNIR Kappa memberikan angka kappa dengan cepat, dengan akurasi dan pengulangan yang sangat baik. Waktu analisis kurang dari 20 detik dan seluruh waktu untuk menyiapkan sampel kurang dari 4 menit. Yang lebih penting, model kalibrasi dapat dipindahkan dari tingkat pulp ke tingkat pulp tanpa memerlukan kalibrasi ulang yang besar.

Properti yang Diukur

FITNIR Kappa mengukur angka kappa dari pulp basah dan kering. FITNIR Kappa menggunakan spektroskopi NIR reflektansi difus sebagai dasar pengukuran. Energi dari cahaya NIR yang menembus sampel diserap oleh lignin. Optik mengumpulkan cahaya pantulan yang difus, mencatat penyerapannya pada detektor inframerah dan menghasilkan spektrum dengan fitur-fiturnya yang unik. Data spektral dari penganalisis kemudian dikorelasikan dengan model kalibrasi yang dibangun sebelumnya untuk menentukan angka kappa. FITNIR Kappa juga dapat dikonfigurasi untuk mengukur viskositas.

Manfaat Utama

- Analisis yang disederhanakan untuk frekuensi pengujian yang lebih besar

- Secara signifikan mengurangi variabilitas operator-ke-operator, meningkatkan akurasi dan pengulangan

- Menghilangkan bahan kimia pengujian yang berbahaya dan mengurangi bahan kimia proses hingga $150.000 per tahun

- Hasil yang lebih cepat untuk penyesuaian yang lebih cepat, meningkatkan efisiensi dan profitabilitas

- Meningkatkan kepuasan pelanggan dengan mematuhi standar kualitas dan memungkinkan produk

pemisahan

Sorotan proyek

Makalah Internasional

Perusahaan Domtar

Perusahaan Domtar

Orange, Texas, Amerika Serikat

Dryden, Ontario, Kanada

Kamloops, BC, Kanada

Papan Pelapis Kraft

(2013)

SW Digester Blowline dan Brownstock

(2015)

Lembaran Pulp Kappa

(2015)

FITNIR Kappa

Mengukur Angka Kappa Menggunakan Spektroskopi Nir

Tonton video singkat ini yang mendemonstrasikan FITNIR Kappa dan fitur-fitur utamanya untuk mengukur pulp basah dan kering, untuk membantu meningkatkan efisiensi dan profitabilitas pabrik pulp kraft.